Masking materials such as tapes, dots and liquid latex can be highly effective in protecting components from ingress of conformal coating.

However, the masking process itself can be labor intensive, difficult and time consuming. It can add a lot to the total conformal coating costs.

Using reusable, custom masking boots offer an alternative solution.

These pre-formed shapes work by fitting simply over the components to be shielded. This process quickly replaces the masking tape and the process time is significantly reduced.

In fact, it has been proven many times that using masking boots as an alternative to tape and boots is labor saving in both the masking and de-masking stages of the coating process.

This switch from tape to custom masking boots can save you lots of time and money.

Three simple reasons why conformal coating masking boots can save you money

- Masking time is reduced. Using custom masking boots can be 4-5 times quicker than masking tape.

- De-masking time is reduced. Again it is much quicker to remove masking boots than tape.

- Masking boots don’t leak as easily as tape and dots. This reliable process leads to lower costs of repair.

This means you can save a lot of money very quickly when switching to custom masking boots.

Find out now how much money you can save by switching to custom masking boots

We are happy to provide a quotation for our masking boots so you can see for yourself how much you can save.

Just provide us with three pieces of information:

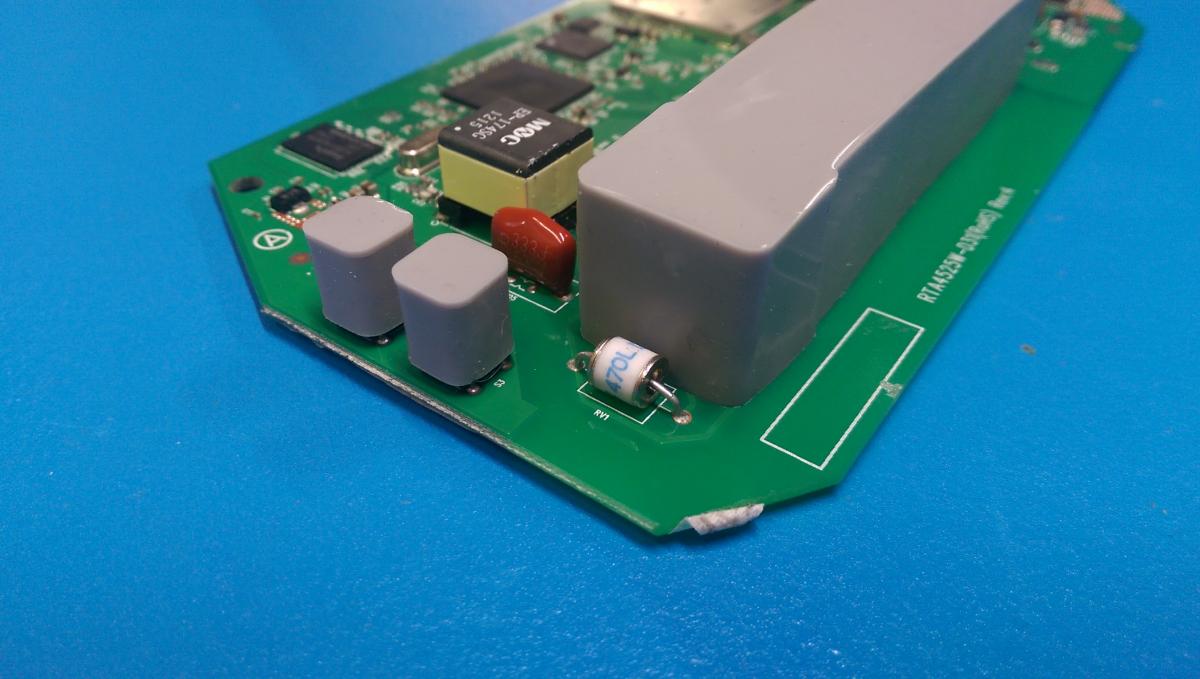

- Provide a picture of the board you wish to test

- Identify the components you need to mask

- Provide the component identification codes (manufacture details etc)

Contact us now to request your quotation for conformal coating masking boots