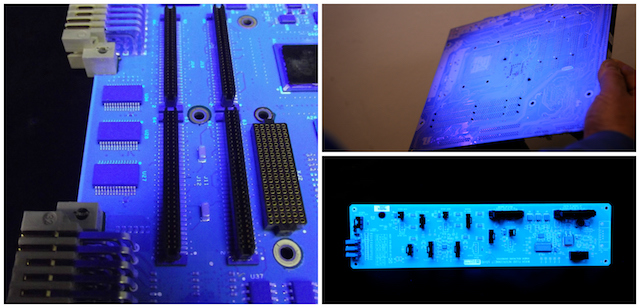

There are several reasons for using a conformal coating or Parylene to protect a printed circuit board (PCB).

These reasons include:

– High insulation protection

– High moisture and humidity protection

– Chemical and temperature resistance

– Ruggedisation

– Improved dielectric properties

– Barrier protection

High Insulation protection

Conformal coatings can provide a high degree of insulation protection for the circuit board assembly during its lifetime when it is applied as a protective film.

The circuit board normally starts with a high level of insulation when it is first manufactured, as it is normally clean.

However, as time passes in the field then the natural environment can degrade the circuit in different ways.

A conformal coating may slow this degradation down.

High moisture and humidity protection

Circuit boards can be very vulnerable to moisture and humidity whilst in the field of operation during its lifetime.

Most conformal coatings are resistant to moisture and humidity.

This can lead to a reduction in affects such as leakage currents, cross talk, electrochemical migration, dendrite growth and arcing across the circuit board.

Chemical and temperature resistance

Some conformal coatings can be resistant to many types of solvents, chemical attack and be heat resistant.

Normally, a circuit board exposed to these types of environment would be degraded but a chemically resistant conformal coating can slow down the effects or even prevent them.

Ruggedisation

Conformal coating can prevent damage from rough handling, installation and reduction of mechanical and thermal stress.

They can strengthen the board.

Improved dielectric properties

Just as the conformal coating can protect the circuit from moisture it can also help to increase the dielectric strength between the conductor parts.

This enables the design of the PCB to be more compact and small.

Barrier protection

The coating material can prevent various types of particulate contamination reaching the surface of the circuit board, which can lead to problems such as corrosion.

The conformal coating is effectively creating a barrier from the contamination during the lifetime of the circuit board.

Ask us how we can help you with your conformal coating project now

Talk to us about your project. See how we can save you money now.

We have the knowledge, tools, experience and the complete solutions whatever you need. We are here to help.

Contact us now.