Conformal coating services

Our global liquid conformal coating services guarantee to offer the lowest price solutions on a like for like basis through our North America, Europe and Asia facilities.

How can we guarantee this?

We provide conformal coating services at source to the customer. This means we benefit from lower costs in our facilities which we can pass to our customers.

We are also experts in what we do and have the full range of conformal coating processes and materials to offer. This helps TFP provide the lowest cost solution without compromise to the customer.

So what can TFP offer you in their coating services?

TFP and our partner companies use a range of application methods, materials and process controls to apply the conformal coating materials.

These include:

- Selective / Robotic conformal coating spraying systems for all types of materials with integrated cure and inspection facilities available.

- Semi automated dipping of printed circuit boards using both vertical and horizontal methods to give flexibility to the process.

- Batch spraying using HVLP gun technology and conformal coating spray booths

- Brush application where price or design are critical and there is a cost saving for the customer

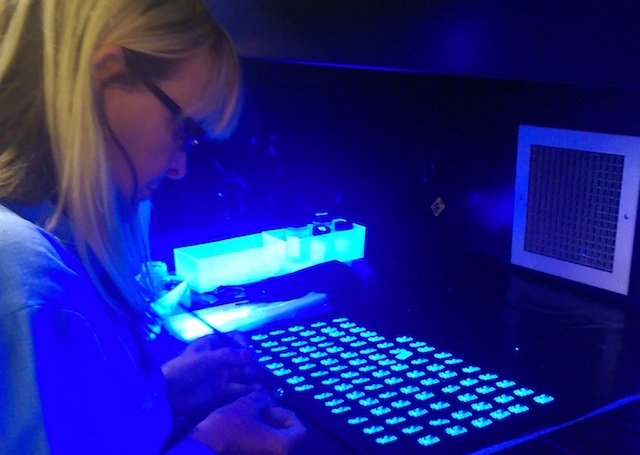

- UV light, Convection and infrared cure facilities where required

- Cleaning and cleanliness testing of the Printed circuit board (PCB) including ionic contamination testing and dyne surface energy pens for control of process.

- Control of curing and drying using infrared / convection batch and inline ovens and ultraviolet (UV) cure conveyors

Our process control is second to none and we control factors like viscosity, temperature and humidity. Our conformal coating production set up applies state of the art knowledge and experience in a practical way that ensures the best services are provided for the customer.

We apply all liquid conformal coating materials including acrylic, polyurethane, silicones, solvent based and UV cure coatings and we use the fullest range of proprietary conformal coatings available from multiple manufacturers including Electrolube, Humiseal, MG Chemicals, Peters, Dow Corning and Dymax.

The critical factors that ensure that we give the best results for a customer are our complete range of conformal coating application systems, our application process control, our state of the art inspection and measurement controls of the applied coatings and our experience in applying successfully nearly all the conformal coatings that have existed and are not available on the market.

We are also ISO9000 and ISO14000 qualified.

Key Facts

- TFP coating services use all types of equipment and application methods

- We have full process controls in place and process to the highest standards

- We can use any coating material a customer specifies in our process

- We are ISO9000 Certified in all of our coating facilities

Contact us

If you would like to know more about coating services or other products and services offered and supported by Thin Film Partners, please do not hesitate to contact us.

Call us on +1 206 257 9787, email us at info@thinfilmpartners.com.