Masking materials and Thin Film Partners

Masking boots, tapes and dots are essential for processing thin film materials that do not selectively coat the surface of a component or circuit.

The coatings that require masking materials in the production process included conformal coatings and other thin film technologies applied with techniques such as Atomic Layer Deposition (ALD) and Molecular Vapour Deposition (MVD).

Our masking materials are designed for thin film processing.

We can help you with your masking material requirements.

Contact us now.

Range of Services

Thin Film Partners LLC offers a range of masking materials for conformal coating and ALD processing.

These masking materials include:

These masking materials meet the highest standards required for liquid conformal coatings processing.

They are also extremely price competitive.

We can help you. Talk to us about your requirements for conformal coating masking.

Contact us now.

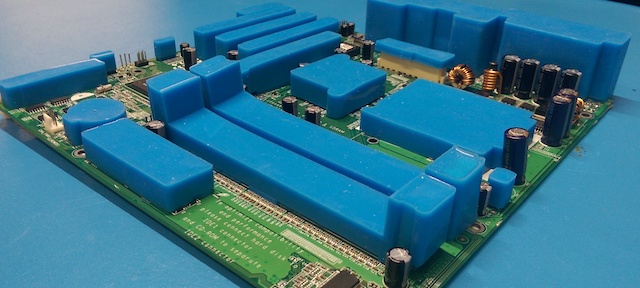

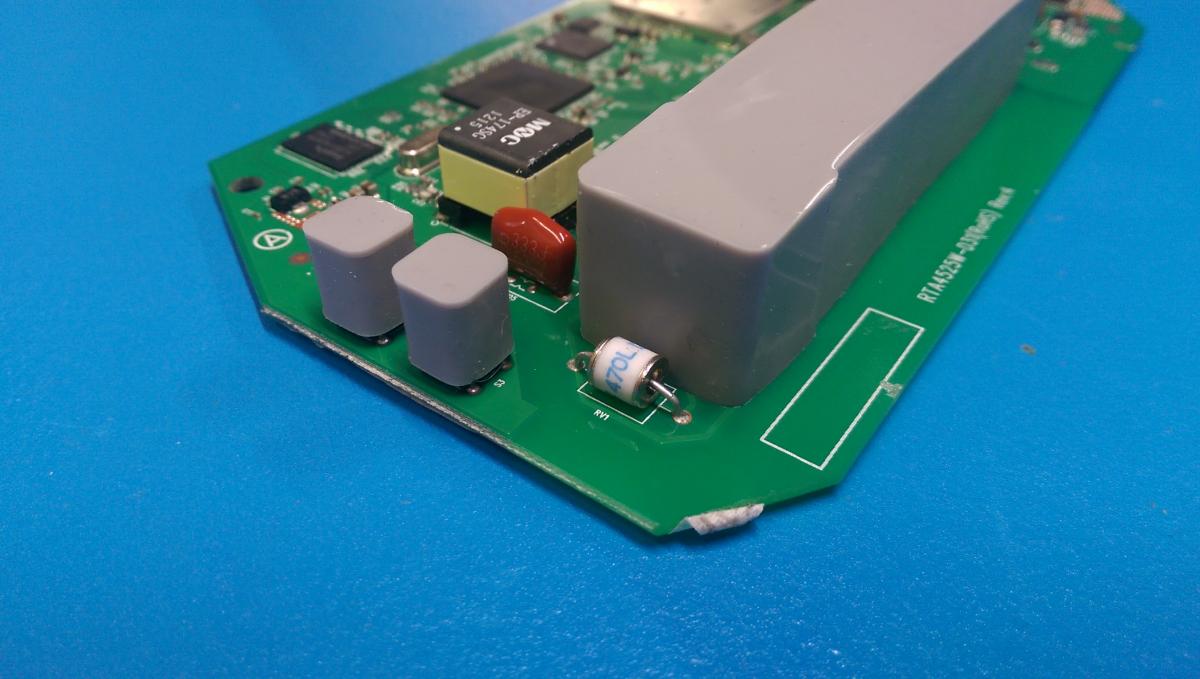

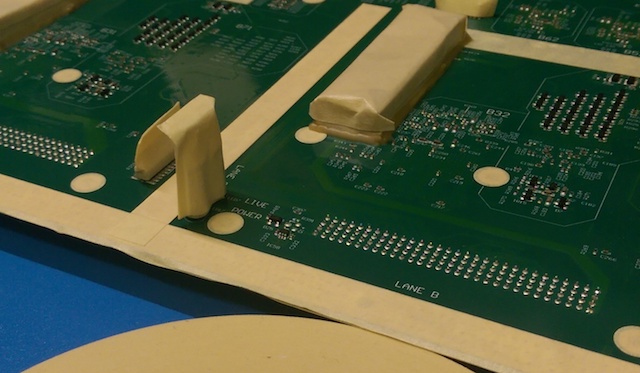

Reusable masking boots

Our masking boots are recyclable and reusable.

They can form an integral part of a full masking solution in coating applications for printed circuit boards. This is for liquid conformal coating process.

Our masking boots provide protection for many different types of components for all conformal coating application techniques.

We can provide both standard and custom boots solutions for a customer depending on their needs.

We can provide quotations and suggestions for how to optimise your masking process.

Find out more about our custom reusable masking boots.

Contact us now.

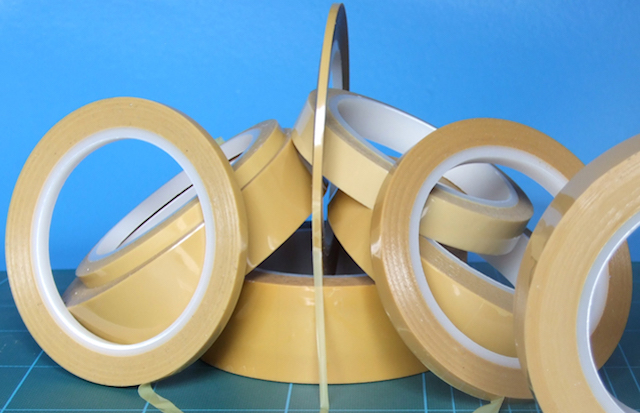

Conformal coating masking tapes

Thin Film Partners offer two types of conformal coating masking tape which compliment each other in the process.

The first tape is used for masking components like connectors on the printed circuit board. The second type is used for masking grounding planes and flat sections such as edges of PCBs.

Find out more about our masking tapes.

Contact us now.

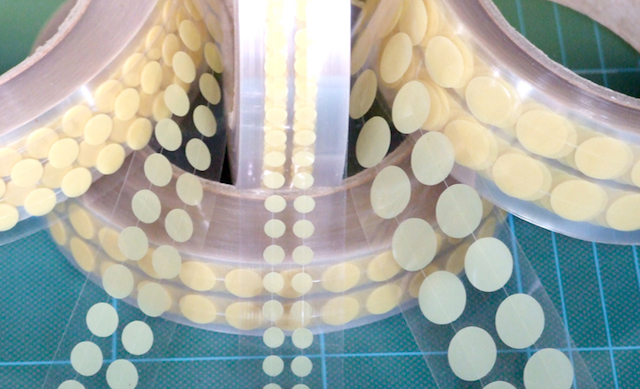

Conformal coating masking dots

Our range of conformal coating masking dots are compatible with all types of conformal coatings including solvent based acrylic, silicone, polyurethane and epoxy materials plus all of the solvent less conformal coatings.

The Conformal coating masking dots sizes include 4.8mm, 6.4mm, 7.9mm, 9.5mm, 12.7mm & 19mm as standard.

Find out more about our masking tapes.

Contact us now.

Why use masking materials in the production process?

Normally, there are areas on the product that must not be coated. Materials like conformal coatings are insulative when dry so will cause problems on components like connector contacts.

Since the coating process tends to be invasive if it is non slective then you have to protect the parts that must not be coated. So, you use masking materials like custom reusable boots, tapes and dots.

Contact us now.

Why have different masking materials for processing?

Our extensive range of masking products includes tapes, dots and masking boots.

This is because there are several variables involved including the volume of production, the type of coating being applied and the complex geometry of the circuit board or part to be masked.

Masking tapes tend to be used for masking low volumes of components on the product. If there are higher volumes then it can be more cost effective to use reusable masking boots. Tapes also work on flat areas that need protecting such as edges of circuit boards or conductive pads.

The masking dots tend to be used to protect areas like mounting holes. Conductivity needs to be maintained and a simple dot can solve the problem.

Finally, masking boots are used where a certain volume of repeat masking is reached. These reusable plugs or shapes cover the whole area very quickly and are highly effective. Typically, the return on investment is very quick compared to tape and dots.

Contact us now.

Why use the masking materials from Thin Film Partners?

The masking materials we offer are used daily in coating services around the world for liquid conformal coatings.

They are tried and tested and meet the highest standards required for the processes.

They are also price competitive and compared with all other materials can save you money.

This means you have the best quality product for the best value on price.

Contact us now.

FAQ Links

- Where are conformal coating masking boots used in the production process?

- How are conformal coating masking boots used?

- Why use conformal coating masking boots in your production process?

- What types of masking boots are available?

- How do I get a quote for custom masking boots?

- What conformal coatings can be used with the masking boots?

- How often can we reuse the conformal coating masking boots?

- What is the temperature limit of the masking boots?

- Why would a conformal coating masking boot leak?

- How do I clean the conformal coating masking boot?

- What is the typical thickness of the masking boot wall?

- Can a custom mark be added to the surface to make identification easier?