Measuring the conformal coating thickness on a printed circuit boards assembly (PCBA) is not a simple process.

The fact of the matter is the circuit board is generally not flat for the majority of the surface.

Therefore, the uneven nature of the board can make it extremely difficult to actually measure any realistic results.

That said, there are several practical techniques for measuring the film thickness on a board, that include both dry or wet film coating.

These techniques include:

Non-destructive eddy current systems

These techniques are explored further below.

Non-destructive eddy current system

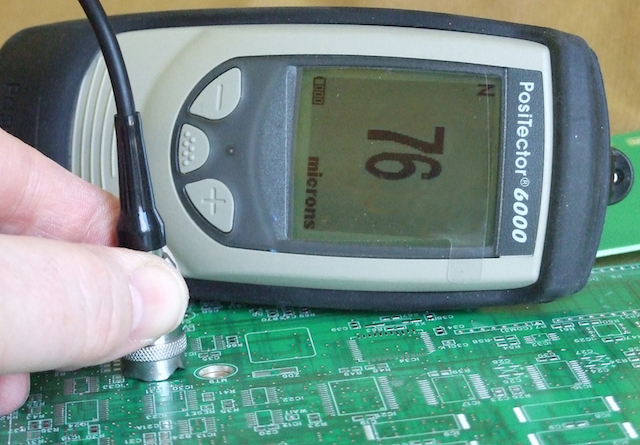

A fast method for measure dry film coating thickness is a system that is using eddy currents.

The method uses a gauge and flying probe for the measurement. The process works by placing the test probe head flat on the surface of the conformal coating and the measurement is almost instantaneous.

The system provides an immediate repeatable result for thickness measurement of conformal coating.

It is also extremely easy to use, the process can be very quick and the accuracy can be within ±1 um depending on the coating thickness and the area being measured.

Since the probe requires a flat surface then test coupons are the ideal method for measuring the conformal coating thickness.

Applying the conformal coating to the test coupons at the same time as the circuit board then provides a permanent measurement and an accurate guide to the coating thickness.

Note that it is also possible that the system can be used directly on circuit boards too.

However, there are several key issues that need to be address when using a probe system like this to get meaningful results.

First, there needs to be metal in the circuit board directly below the test probe point. Otherwise, the system cannot work.

Second, their needs to be a flat area large enough on the PCBA for the test probe to be placed. The smallest practical probe is approximately 6mm diameter so any area smaller than this requiring to be measured is not practical.

Finally, the surface area on the circuit that is to be measured needs to be flat for the probe. If not then there will be errors in the measurement.

Micrometer screw gauge

A lower cost method for measuring conformal coating thickness is using a simple system like a calibrated micrometer screw gauge that can measure down to ± 10 um.

The process works as follows.

First you measure a point on the board or test coupon before coating. Then you apply the coating, cure and measure the test coupon again at the same point.

The difference in the two measurements gives you the conformal coating thickness.

A couple of key issues with a micrometer are ensuring the conformal coating is cured hard enough since if it is soft it could compact during measuring and give a false reading.

Also, do not measure one point. Take an average of at least 3 or 4 points since errors in use of micrometers are high and this will give a better result statistically.

Wet film gauge

A final method for measuring conformal coating thickness is a wet film measurement technique. This is very cost effective although a little cumbersome.

The technique uses a comb with different size patterns that is placed in the wet conformal coating during the application process. The imprint left on the comb indicates the wet film thickness.

Knowing the solids content of the conformal coating material means that the material thickness can be calculated.

Ask us how we can help you with your thin film projects now

Talk to us about your project. See how we can save you money now.

We have the knowledge, tools, experience and the complete solutions whatever you need. We are here to help.

Contact us now.