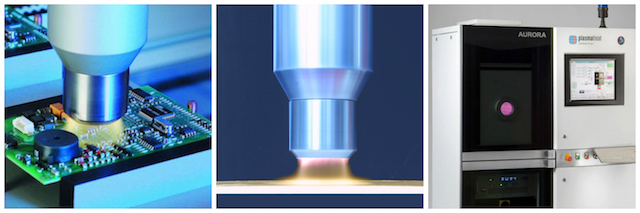

Here are five key reasons to use plasma cleaning and surface treatment to improve surface properties:

- Plasma cleaning can clean nearly any type of surface and this will improve the adhesion of most coatings and increase the surface energy of the product.

- Many wet chemistry cleaning processes that are used to achieve the same result can be eliminated. Methods using cleaning chemistries, water processing, and drying energy can become redundant.

- The plasma cleaning process can activate a surface of the product by changing the surface energy of the substrate or part. This significant improvement in surface energy can lead to better adhesion for alternative coatings that may normally have difficulty adhering to surfaces without the treatment.

- The plasma cleaning process is a simple, safe and environmentally friendly technology that has been proven to work time and again.

- The plasma cleaning process can be both a batch (offline) and inline process depending on the requirements.

This means the plasma process can be highly effective for many different products. As a result, plasma cleaning is in use in almost all areas of industrial manufacturing.

Ask us how we can help you with your cleaning requirements?

Talk to us about your project. See how we can save you money now.

We have the knowledge, tools, experience and the complete solutions whatever you need. We are here to help.

Contact us now.