Plasma coating is the application of a Nano-coating material onto a surface of a substrate via a plasma gas.

Plasma technology is based on a simple physical principle. Matter changes its state when energy is supplied to it. Solids become liquid. Liquids become gas. If additional energy is then fed into a gas by means of electrical discharge it eventually ionizes and goes into the energy-rich plasma state.

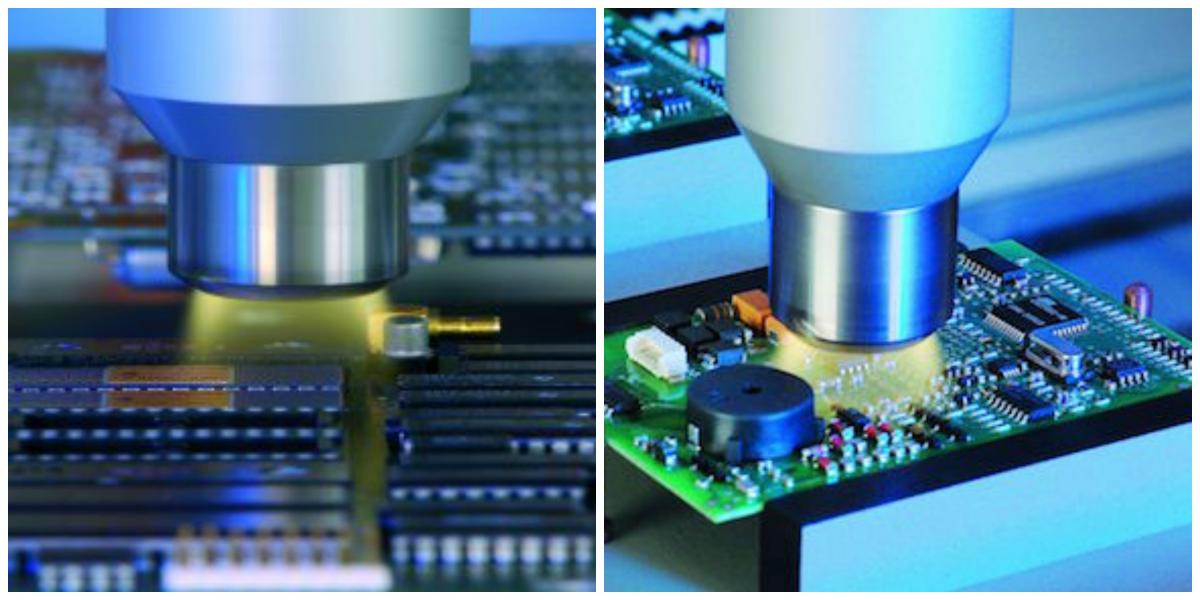

The Plasma created can be used for applying Nano-coatings. The Nano-coating material is injected into the plasma gas via a jet nozzle. The plasma excites the coating material and this increases the coating materials reactivity. The plasma coating is then applied to the surface.

Due to the excited nature of the coating material in the plasma, the Nano-coating coverage is optimized and the bonding to the surface is improved.

The types of Nano-coatings applied can be hydrophobic (water repellent) and hydrophilic (water absorbent). This means you can change the wetting energy of the surface.

The choice of coating type will depend on your requirements. The plasma coating process can be used to coat different materials like metals, glass, ceramics and plastics.

Ask us how we can help you with your plasma coating requirements

Talk to us about your surface treatment project now. See how we can save you money now.

We have the knowledge, tools, experience and the complete solutions whatever you need. We are here to help.

Contact us now.