For a conformal coating to be effective in protecting a circuit board it should be applied evenly over the circuit board assembly and it should have good adhesion.

Otherwise, the circuit may suffer an early failure in the field.

For good coverage and good adhesion the surface properties of the circuit board should be compatible with the conformal coating.

If the conformal coating and the surface are not compatible then there could be problems with the conformal coating de-wetting from the surface or delaminating.

Therefore, to achieve optimum performance of the coating it may be wise to ensure the surface is compatible with the conformal coating itself.

Traditional methods of surface improvement for circuit boards

Improving the surface energy of a circuit board substrate before conformal coating has been done in production ever since conformal coatings were first used.

Traditionally, there have been two methods to achieve this.

These two techniques are:

- Cleaning. Washing the circuit board using a wet chemistry solution.

- Adhesion promotion. Applying undercoat and priming the surface.

The two techniques either clear away (cover up) contamination or provide a better surface for the conformal coating to adhere to.

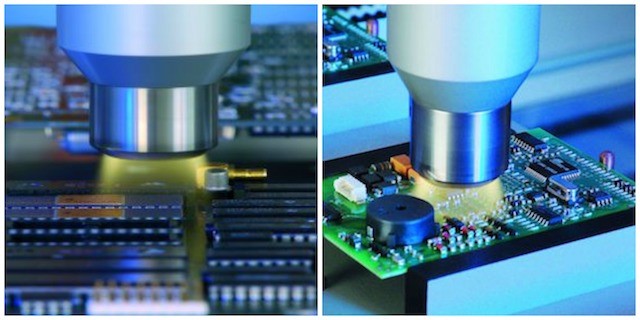

Now, there is an alternative method for improving cleaning and adhesion that is using plasma.

What is plasma?

Plasma is an energy-rich gas state that can be used to modify the surface of a product to improve its performance.

It is based on a simple physical principle.

Matter changes its state when energy is supplied to it. Solids become liquid. Liquids become gas.

If additional energy is then fed into a gas by means of electrical discharge it eventually ionizes and goes into the energy-rich plasma state, the fourth state of matter.

Plasma is created and this is used to improve substrate surfaces.

How can Plasma be used to improve the performance of a coating on the surface?

Plasma can clean, activate or coat nearly all surfaces. These surfaces include plastics, metals, (e.g., aluminum), glass, recycled materials and composite materials.

This means the plasma process can be highly effective on many different products.

Plasma cleaning can be used in two highly effective ways.

These are:

- Clean the surface to be 100% contamination free. The surface will be free of residues and contamination.

- Activate the surface by changing the surface energy. This would allow easier bonding and better adhesion to the surface.

These properties make it a highly practical technique for improving the surface performance of a product.

So why use plasma to clean and treat the surface of circuit boards?

There are a few reasons why plasma cleaning and surface treatment of printed circuit boards is an excellent process.

They include:

- Plasma cleaning can clean the surfaces of a circuit board to improve adhesion and increase the surface energy of the substrates.

- Plasma can eliminate wet chemistry cleaning processes. Costly non-value added methods using cleaning chemistries, water processing and drying energy are not required.

- The plasma can activate the surface of the circuit by changing its surface energy. This allows the conformal coating to bond easier and have better adhesion to the surface.

- The significant improvement in adhesion through the plasma process could also allow the use of alternative coatings that may have originally been difficult to adhere to surfaces without the treatment.

- The plasma cleaning process is a simple, safe and environmentally friendly technology.

- The plasma process has both batch (offline) and inline capability.

This means the plasma process can be highly effective on printed circuit boards where conformal coatings are being applied.

Ask us how we can help you with your conformal coating requirements?

Talk to us about your project. See how we can save you money now.

We have the knowledge, tools, experience and the complete solutions whatever you need. We are here to help.

Contact us now.